The first step of SKF bearing selection is to understand and document:

- the required performance

- the operating conditions and assumptions of them

- any other application prerequisites

An application can set various requirements on the SKF bearing solution. Common factors include:

- bearing life

- speed capability and ability to withstand applied acceleration levels

- precision of the radial and axial position of the shaft

- ability to cope with low or high temperatures or temperature gradients

- generated noise and vibration levels

The relative importance of these performance factors can influence the nature of the path you take through the steps of the bearing selection and application analysis process.

You should evaluate the operating conditions in as much detail as possible. The most important operating parameters are:

- load

- speed

- temperature

- lubricant and lubricant cleanliness

Usually these can be determined from physical and mechanical analysis of the application, or from experience with similar applications. Make sure that any assumptions made are clearly documented.

Operating conditions typically vary over time, e.g. in variable speed applications or because of seasonal temperature changes or increased output power. The range of the variation is important. In some cases, both limits of the range may be important, whereas in others, only the lower or the upper limit may be.

In order to optimize a design, you may need to loop through various steps of the bearing selection process. To minimize these, review and prioritize any application prerequisites, such as:

- available radial or axial space

- shaft diameters defined by shaft strength requirements

- lubricant choice determined by other components in the application

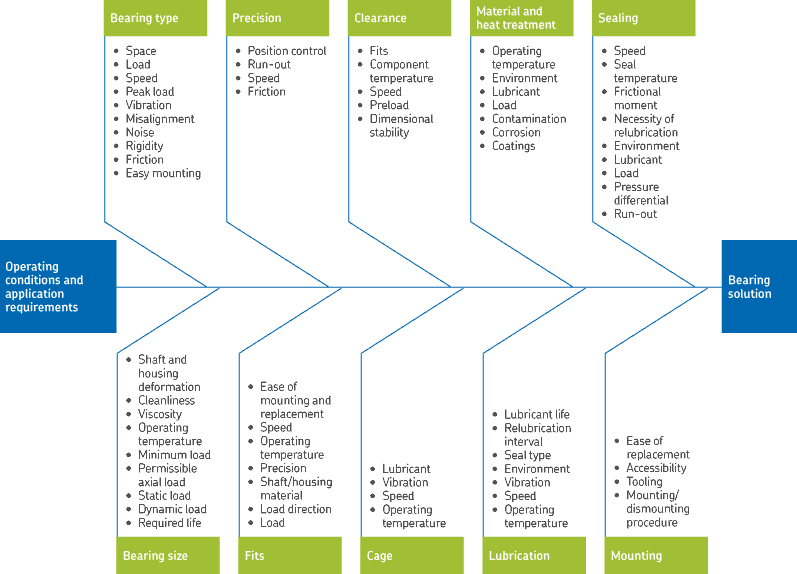

The drawing shows the relationship between principal operating conditions, application requirements and various aspects of a bearing arrangement’s design. The lists are not comprehensive and you may have to consider other factors and interrelationships, such as cost and availability, when striving to obtain a robust and cost-effective solution.